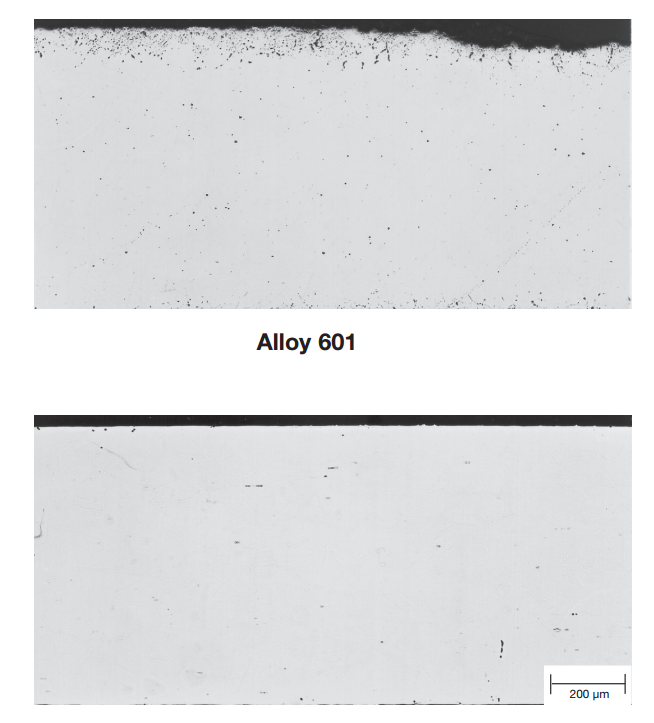

HAYNES® 214® alloy has also been tested in environments with higher levels of chlorine contamination. The photomicrographs to the right are for samples exposed to a mixture of air and 2% chlorine for 50 hours at 1830°F (1000°C). Once again, the black area at the top of each photograph represents actual metal loss experience. Alloy 601 exhibited 2.0 Mils (51 µm) of metal loss, and an average internal penetration of 6.0 Mils (152 µm), for a total average metal affected of 8.0 Mils (203 µm). Results for 214® alloy, by contrast, were 1.0 Mils (25 µm) of metal loss, 1.0 Mils (25 µm) of average internal penetration, for a total average metal affected of only 2.0 Mils (51 µm). These results are consistent with the results for lower chlorine level, longer-term tests given on the previous page.